以太网和通信模块好货推荐

厦门雄霸电子商务有限公司

本店由供应网运营支持

参数规格

| 电压 | 60V | 电流 | 60A |

| 体积 | 0.6m3 | 重量 | 1.2KG |

| 颜色1 | 黑色 | 颜色2 | 白色 |

产品介绍

所以通过点动要实现两原点统一!系统概述及设计方案 1、胎面线原运行操作 (1)宽度测量—操作员手动卷尺测量并记录 (2)牵引速度—手动调节电位器改变变频器的输入电压改变生产线的牵引速度 2、增加测宽调速功能的必要性和可行性分析 (1)宽度测量人为因素引起的误差比较大,不可控。牵引速度手动调节如果没有宽度的时时趋势很难。需要不断手动测量,改变速度,直至宽度、重量合适为止。另外,数据的记录和保存在手动情况下影响因素太大,而且数据量比较小,很难真实地反映生产线上的趋势变化,当然统计中得到的过程控制参数就没有太大的参考价值。所以实现智能测宽,自动调速,时时数据保存,就显得十分重要。 (2)分析生产线牵引速度一般在25米/分钟左右,由客户要求对宽度控制精度要求比较高,允许公差在正负1毫米,重量只需上位显示保存,不做为反馈参与调速。因此只需宽度采集频率要高,控制算法合理及可满足使用要求。 3、系统设计 (1)宽度测量采用1000点测宽镜头直接与上位单功通讯,采集频率可以达到100HZ,足够反馈要求,为使测量精度更高,采用两个镜头,使得宽度理论测量精度在0.2mm以内。 (2)速度控制算法模型采用PID模式。 (3)整个系统的工作原理图如下:

二、项目实施技术处理 对本项目实施中有以下三点点功能比较突出。 (1)1000点镜头的使用 采用1000点镜头直接与上位连接,采集周期很短,宽度反馈的时时性很好,就为调速提供了有利的反馈参照。另外我公司目前测宽大多数需要外加一套测宽主机。如果在以后的用到类似的测量中,带上位PC的话,可以不加测宽主机,以节约成本,同时也减少了硬件故障点。使系统更稳定。 (2)设计适合于现场的速度控制算法简单介绍如下: 系统速度控制采用两步来操作,在刚开是生产时,观察宽度趋势的同时采用手动调节速度,当前宽度至调节死区范围内即可切换为自动控制。 系统手动采用脉冲量的高次函数输出,使得在加速和减速分别通过一个点动按扭既可以实现速度大范围粗调,又可以速度小范围精调。操作很直观、人性化,手动模式下在规格刚生产时控制效果好,有效减少费料。

自动调节采用变异的PID模式算法,简单介绍处理过程如下 1设定时间常数;2设定比例系数;3对趋势值和设定值的差值积分;4计算速度变化量并输出;5在差值符号变化的时候积分量归零。

整体速度控制过程的结果如下图

(3)系统嵌入QS9000中过程统计。 本系统在历史数据处理和统计方面增加了QS9000的过程统计,以此分析这个系统的控制能力,得到系统的能力指数和性能指数等关键信息,方便用户及时调整工艺,节约成本。

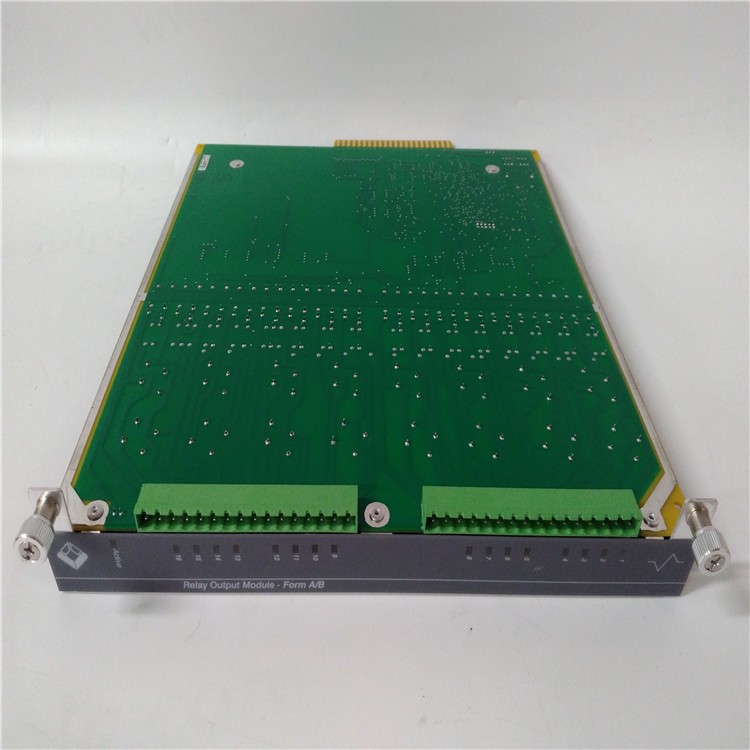

历史趋势图 在系统中自动对历史数据分析,形成SPC系统中的X(bar)—R图,信息齐全,可以很直观的看到系统的能力指数等统计信息,并对工艺卡的参数修改提供了很强的参照依据。自动化*热烈的主题之一是关于关键控制功能是集中还是分散的争论,在这些自动化架构中, 安全系统的处理常是关键的讨论点。这个主题调查一个汽车制造商在分散方式下怎样解决问题。 汽车模型变更需要连续更改汽车生产线。为更好地处理这些使用解决安全标准的系统的更改,在大的北美汽车制造公司的工程师首先想建立一个工业通信平台,这个平台灵活,从而电气人员能简单编程以及解决问题,并能容易地与第三方组件(例如机器人、阀组)在现场总线网络上集成。考虑到这些要求和硬接线与传统的安全继电器(与安全兼容的)的结合,工程师选择Simatic 带Profisafe的容错PLC技术,因为它提供快速、易适应、*少停机时间的控制可靠的安全解决方案。下图描述制造商使用Profisafe的设计规划:

Profisafe设计概貌

Profisafe设计概貌

from the controller 100, about 550 control points away from the controller 200, about 320 control points of the wastewater system controller 500. The ControlNet network is a bus structure. based on the producer / consumer model, each node station acts as a producer to package and send the data to be sent to the network according to a certain format, Other node stations on the network extract data as consumers on demand, with high communication efficiency. The network communication rate is 5mbps, the transmission medium is the same shaft thick cable, and the impedance is 75 Ω. The connection between the network communication cable and each node station is realized through T-connector, which has the advantages of simple installation and commissioning, stable connection and small maintenance. When there are only two nodes in the network segment, the maximum transmission distance is 1000m. With the increase of nodes, the maximum transmission distance will decrease. The calculation formula is 1000 - (n-2) × 16.8m, where n is the number of nodes. The lower computer adopts the PLC of ControlLogix series of AB company. The PLC controller adopts logix5555 of 32-bit bus, 750k basic memory and 1.5m extended memory. The mutual standby between dual CPUs is realized through SRM hot standby module, which realizes the unification of the whole plant on the model of PLC, and the upper computer adopts ifix3 The control software of 5 adopts OPC communication mode and is connected to the control network through the Ethernet of the upper computer, which provides convenience for the network connection of the auxiliary workshop. The auxiliary workshop monitoring network adopts the principle of "network layering and centralized control". (1) The network is divided into Ethernet layer and ControlLogix layer. The two networks are independent and interrelated. A: Centralized monitoring shall be set up in the fine treatment and dosing control room to control and monitor the fine treatment and dosing. In order to know the operation status of the polishing and dosing equipment in time during patrol inspection. B: Centralized monitoring is set up in ultrafiltration, reverse ultrafiltration and reverse osmosis to control and monitor the ultrafiltration, reverse ultrafiltration and reverse osmosis equipment. In order to know the operation status of ultrafiltration and reverse osmosis equipment in time during patrol inspection. C: Centralized monitoring is set in the water treatment control room to control and monitor the boiler make-up water system (remote I / O), water purification system (remote I / O), raw water system (remote I / O), ash and slag removal system (remote I / O) and wastewater system (remote I / o). At the same time, it is connected with each remote I / O station through communication, and controls and monitors each remote I / O station. D: Others. Set up monitoring points where monitoring is needed to facilitate control and adjustment

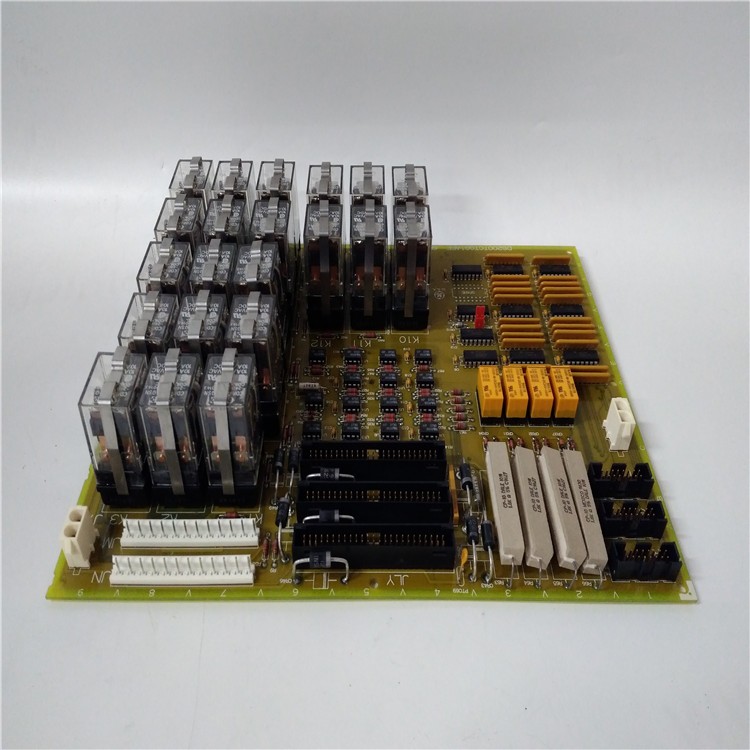

用软件代替继电器的倾接线.改变控制要求方便。PLC采用有微型计算机为核心的电子线路,是多种电子式继电器、定时器和计数器的组合体,它们之间的连线(即内部接线)通过指令用编程器进行.如果按照现场要求改变控制方式,修改控制线路,只需用编程器对指令进行修改即可,方便。

(3)用半导体元件将继电器有触点控制改为PLC无触点控制,大大提高了。J靠性相稳定性,将原继电器盘控制装町的故障,如继电器线圈烧坏、线圈粘连、线阁吸合不紧、接点脱落等继电器本身的故障彻底。

(4)扩展I/0饥架有两种电源型号选择:①使用100~120VAC或200~240VAC电源;②使用24VDC电源。输入设备如按钮、选择开关、行程开关、压力调节器等可用24VDC电源作为信号源,这样可避免由于生产环境温度过高而造成行程开关、压力调节器等短路现象,提高了维修工人的性,降低了维修工作埠。输出端可通过200~240VDC电源直接驱动电磁阀、接触器等输出负载。

(5) 除了有CPU错误、电池错误、扫描时间错误、存贮器错误、Hostink错误、远程I/O错误等自诊断功能和能判断PC机自身故障外,对应于I/O每一个点都有信号指示灯,指示I/0的0N/OFF状态,根据I/O指示灯的显示可准确、快捷地判断PLC外围设备的故障。

(6)根据控制要求,可方便地构成合适的系统,且便于扩展。如果硫化机需增加和改进外围控制系统,在主CPU上再加扩展元件,以后设备需联网,可很方便地构成系统。

3 如何给硫化机编程

(1)确认硫化机正常运行的整个过程必须做那些动作,以及它们之间的相互关系。

(2)确定行程开关、按钮等作为发送输入信号到PLC的输入设备所需的输入点数;电磁阀、接触器等作为接收来自PLC输出信号的输出设备所需的输出点数。然后给每一个输入和输出点指定一个I/0位,同时分配“内部继电器”(M)或工作位和计时器/计数器。

(3)根据输出设备之间的相互关系和控制对象必须动作的顺序(或时间),画出梯形图。

(4)如果使用PC(个人电脑),HMI(人机界面)或FCP30(PLC编程软件)就可以直接用梯形图逻辑编PLC程序。

(5)利用PC检查程序,并纠正错误,然后试运行程序,并观察硫化机的运行,是否与我们的要求相一致,然后修改程序,直到程序完善。

4 硫化机自控系统的常见故障

采用PLC控制的硫化机故障率相当低,故障一般主要发生在下面几个方面。

(1)输入设备

象行程开关、按钮、转换开关经过多次反复动作后,会产生松动、不复位等现象,有的甚至会损坏。

(2)输出设备

由于环境潮湿和管路泄漏现象,使电磁阀进水,发生短路,烧坏电磁阀。信号灯也经常有烧坏的现象。

(3)PLC

由于输出设备多次短路,产生高电流,冲击PLC内部的输出继电器,而使输出继电器触点熔化而粘连在一起,损坏继电器。

5 维护和保养

(1)在安装PLC时,必须远离下列环境:腐蚀性气体;温度剧烈变化;阳光直射;灰尘、盐和金属粉末。

(2)每组输出单元经220VAC输出,至少必须加一个2A250VAC的保险丝,当该保险烧断,一定要检查该组输出设备是否有异。若不检查就马上换上新保险,则易损坏输出单元的继电器。

(3)平时要注意观察电池报警指示灯,如果报警灯闪,必须在一周内更换电池,电池平均寿命为8年(在室温25℃以下)。

(4)当CPU和扩展电源拆下检修后,安装接线时一定要接对,否则很容易烧坏CPU和扩展电源。temperature central air conditioners, fully enclosed screw chillers, semi enclosed screw chillers and air-cooled and hot water units. Schneider Electric automation products have been successfully applied in fully enclosed chillers and semi enclosed air-cooled units. 2. Product introduction and = s = Product Scheme

Relatively speaking, the technical content of the fully enclosed screw chiller is higher, so the control system is complex, while the air-cooled chiller is simpler.

Therefore, the fully enclosed screw chiller was first composed of micro PLC and xbtf of = s = company, which is mainly composed of:

Tsx3721 tsxdmz25dr tsxdsz08r5 tsxaez801 (1-3pcs) in this control system, the control principle and process are not very complex, but the fault alarm and protection requirements of the machine are high,

Therefore, very complex protection logic can be seen in the program; In addition, the machine has a special place, that is, there is a data table composed of thousands of discrete data. The operation state of the machine is carried out according to the data table. In a sense, the high operation efficiency of the central air conditioner depends on the accuracy of the table. In this way, the data table becomes the know how of China's air conditioning enterprises. When using micro PLC, the customer makes good use of the function of mutual conversion between constants and internal words in micro PLC, stores these data in the constant table, and obtains accurate data by using the table lookup function.

The air-cooled unit is relatively simple in technology, and its market price is lower than that of the fully enclosed unit, which has cost requirements for its parts. Therefore, in the design, Twido PLC with relatively higher cost performance and Schneider Electric's new touch screen xbtg are adopted. The basic composition is: in 2005, with the entry of a large number of domestic enterprises, the central air-conditioning enterprises, The price has dropped significantly, and the cost pressure of the industry has suddenly increased. Therefore, the customer requires a low-cost alternative to the micro PLC control scheme with relatively high cost, so as to reduce the cost; based on this starting point and considering the successful application of Twido PLC in its semi closed air-cooled unit, the customer recognized Twido PLC which is very close to micro in quality and performance. Therefore, we gave Twido a scheme to replace micro, and gave priority to the multi-channel analog module newly launched by Twido in this scheme, so that the cost of the system is greatly reduced compared with the original. The new configuration is: in this application, we have encountered a technical difficulty: how to complete the table lookup function of thousands of variables in Twido PLC? At present, there are up to 3000 memory words in Twido, so thousands of data will occupy a lot of memory resources. In order to solve this problem, we make good use of the programming skills of subroutines, divide thousands of data into dozens of subroutines, and use the same data area in the subroutine, which solves this problem very well. Moreover, since each subroutine has less than 100 data, its query speed is faster than before.

In this system, we still choose Schneider Electric's new touch screen XTBG to cooperate with Twido. In the process of programming xbtg, I found

联系方式

店铺好货推荐

发送询价单

立即询价

立即询价

进入店铺

进入店铺

更多详情

更多详情